Description

Packed columns are often used to implement the basic process engineering unit operations distillation, absorption and desorption. Still, the design of packed columns is subject to great uncertainties. One of the main reasons for this is the so-called "maldistribution", an uneven distribution of the liquid across the column cross-section, which forms with the run length of the liquid in the packing. This liquid maldistribution results in concentration differences in the column cross-section which in turn causes separation efficiency losses. Even to date, the prediction of liquid distribution in packed columns is insufficient. [1]

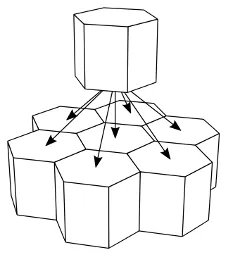

The scope of the cooperation project "Cell Model for Design of Packing Columns and Liquid Distributors" (AZ-1033-12), funded by the Bavarian Research Foundation, was the improvement of the aforementioned prediction of liquid distribution. For that purpose, experimental investigations on liquid distribution in packed columns were carried out in three facilities of the project partners. The main part of the measurements were conducted at the Technical University of Munich in a 1.2 m diameter packed column with a water / air system, covering a wide range of experimental and operating parameters – packing type, packing height, liquid distributor, liquid and gas load. [2–4] At RVT Process Equipment GmbH, experiments were performed in a 2.0 m diameter packed column, again with the system water / air, with the scope on reviewing the scalability of experimental data on industrial scale column diameters. Linde AG carried out experiments in a 0.4 m diameter packed column, with the special feature of an isohexane / nitrogen system.

Evaluation of the experimental data was finally used to further develop and validate a cell model [5] developed by WelChem GmbH for the prediction of liquid distribution. The cell model was significantly improved by the implementation of fluid-dynamic dependencies and a refined mechanism of the flow at the column wall [6]. Following successful validation of the TUM–WelChem Cell Model, it is now used for the design of liquid distributors with optimized drip point grid [7]. In the field of process simulation, the use of a so-called "parallel column model" also offers potential applications for the TUM–WelChem Cell Model in order to predict the influence of liquid distribution on the separation efficiency of packed columns. [8]

[1] A. Mersmann, M. Kind, J. Stichlmair: Thermische Verfahrenstechnik: Grundlagen und Methoden. 2nd ed., Springer, Berlin 2005.

[2] F. Hanusch, S. Rehfeldt, H. Klein: Flüssigkeitsmaldistribution in Füllkörperschüttungen: Experimentelle Untersuchung der Einflussparameter. Chem. Ing. Tech. 2017, 89 (11), 1550-1560. doi 10.1002/cite.201700015

[3] F. Hanuš, S. Rehfeldt, H. Klein: Zellenmodell zur Auslegung von Packungskolonnen Teil 1: Untersuchung der Flüssigkeitsverteilung in Füllkörperpackungen. Chem. Ing. Tech. 2015, 87 (8), 1063-1064. doi 10.1002/cite.201550041

[4] F. Hanusch, S. Rehfeldt, H. Klein: Liquid Maldistribution in Random‐Packed Columns: Experimental Investigation of Influencing Factors. Chem. Eng. Technol. 2018, 41 (11), 2241–2249. doi 10.1002/ceat.201800467

[5] A. Wild, V. Engel, F. Hanuš, S. Rehfeldt, H. Klein: Zellenmodell zur Auslegung von Packungskolonnen Teil 2: Das WelChem‐ Zellenmodell zur Berechnung der Maldistribution. Chem. Ing. Tech. 2015, 87 (8), 1103. doi 10.1002/cite.201550077

[6] F. Hanusch, R. Kender, V. Engel, S. Rehfeldt, H. Klein: TUM-WelChem cell model for the prediction of liquid distribution in random packed columns. AIChE J. 2019, 65 (8). doi 10.1002/aic.16598

[7] F. Hanusch, M. Künzler, M. Renner, S. Rehfeldt, H. Klein: Liquid distributor design for random packed columns. Chem. Eng. Res. Des. 2019, 147, 689–698. doi 10.1016/j.cherd.2019.05.035

[8] F. Hanusch, V. Engel, R. Kender, S. Rehfeldt, H. Klein: Development and Application of the TUM-WelChem Cell Model for Prediction of Liquid Distribution in Random Packed Columns. Chem. Eng. Trans. 2018, 69, 739–744. doi 10.3303/cet1869124

Project Partners

The research proposal was developed together with WelChem GmbH, who also provided their column design software TrayHeart as well as the original version of the WelChem Cell Model.

As part of the project, RVT Process Equipment GmbH provided their liquid distributor test facilities for liquid distribution measurements in a packed column with 2.0 m diameter. Furthermore, RVT supplied the other project partners with random packing for experimental investigations.

Linde AG conducted measurements in a packed column with 0.4 m diameter – with the special feature, that this column was operated with an isohexane/nitrogen system.

Funding

The cooperative project Cell Model for Design of Packed Columns and Liquid Distributors was funded by the Bavarian Research Foundation (AZ-1033-12).

Liquid distribution raw data

Measurement data of the liquid distribution experiments can be downloaded via

http://www.ext.apt.mw.tum.de/maldistribution_en/data.

Proceed with your login details.

Login details for access on liquid distribution raw data

Please fill in the linked form and click on "send request", to get access on our liquid distribution raw data. Your request will be attended promptly and you will get the login details via e-mail.