The research project: an overview

To reach the aim of the Paris agreement, Germany wants to be climate-neutral by 2050. To push the energy transition, government funding is indispensable. This should draw attention of the society that advancing and anthropogenically accelerated global warming can no longer be ignored. Particularly, It should convince and support the industry to invest in sustainable technologies.

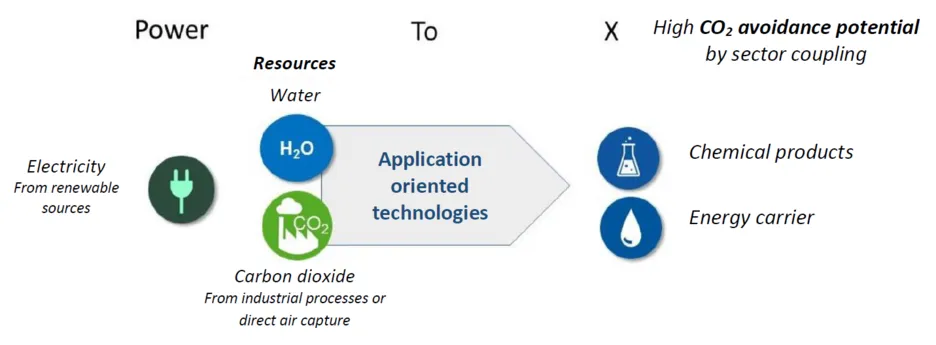

The Kopernikus-projects funded by the German Federal Ministry of Education and Research is one of the largest research initiatives in Germany to accelerate the energy transition. In the associated power-to-X (P2X) project renewable electricity, CO2 and water are converted to valuable chemical products (see Figure 1). X is representative for gases like hydrogen, fuels, chemicals and plastics.

After selecting promising technologies, in the second phase of the P2X project the focus is on two technology paths: “hydrogen as energy-vector” and “synthesis gas as energy-vector”. Both technology paths start with an electrolysis and are developed according to their application sectors – mobility, energy utilization and chemistry – to achieve complete value chains with the aim of maximum CO2 reduction. This should create a basis for realization in the third project phase.

„Hydrogen as energy-vector“ (technology path 1)

The proton-exchange-membrane-electrolysis (short: PEM) enables the conversion of renewable energy and water into hydrogen which is considered as energy carrier in the first technology path. Goal is the reduction of the iridium-loading of the anode electrode while maintaining the same efficiency and the scale-up of the PEM-technology for the predicted growth of the electrolysis market. Iridium is a rare and expensive material, however it is crucial for the catalyst activity to split water at the anode.

Our task comprises the overall electrolysis process including water treatment and purification. The sensitivity of specific parameters on the system efficiency is investigated using simulation tools. Considering the fluctuating availability of renewable energy an optimization model will be developed to calculate the minimal hydrogen evolution costs of a load flexible electrolysis for the production of zero-emission hydrogen at present conditions.

„Synthesis gas as energy-vector“ (technology path 2)

Synthesis gas is educt for the production of different downstream-products and focus of the second technology path in the project. Process chains including the high temperature co-electrolysis as key element will be further developed and should offer alternatives to the conventional and emission-intensive synthesis gas production for example from natural gas. In the co-electrolysis water steam, CO2 and renewable electricity are directly converted into synthesis gas. Our task is to simulate different process options for the integrated production of different downstream-products based on high-temperature electrolysis, as well as the comparison to conventional generation.

One of the prioritized process chains in the P2X project is the production of synthetic fuels. Thereby CO2 is filtered from air by the so called direct air capture process. In the co-electrolysis the CO2, steam and electricity are then converted into synthesis gas. In the next step latter is combined to long-chain hydrocarbons in the Fischer-Tropsch-reactor. The hydrocarbons are further treated to obtain synthetic fuel. For this process chain a containerized solution should be developed within the project. A summary to the current state of the power-to-fuel plant can be watched here.

.