FormEL - Investigation of process-quality-interdependencies between the formation process and the end-of-line quality check with the aim of an optimization and functional integration of these final production processes

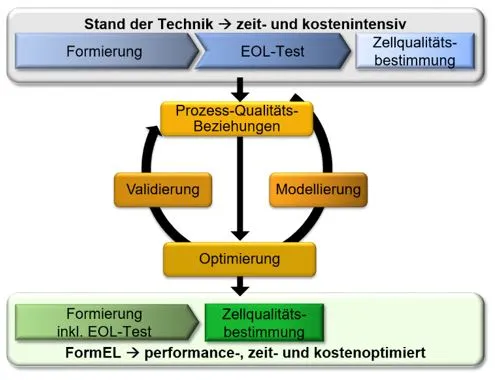

FormEL adresses the investigation of process-quality-interdependencies between the formation process and the end-of-line quality check with the aim of an optimization and functional integration of these final production processes of lithium-ion batteries. Conventional formation and end-of-line test (EOL-test) procedures last several hours or days. These state-of-the-art formation and EOL-test procedures will be improved in FormEL regards time, costs and quality. Therefore, the interdependencies between the formation process and the EOL-tests are identified and analyzed with respect to the resulting and diagnosed cell quality. This process-quality-interdependencies are determined by parameter studies and are used in order to develop detailed models.

Therefore, it is necessary in Project FormEl to set up models for analysing the process-quality-interdependencies and describe formation and cell parameters from EOL-test adequately. As comparison industrial reference processes for formation and EOL-test are investigated and further improved. At the same time new methods and approaches for formation and EOL-testing are pursued. After successful validation these new methods and approaches are implemented in a first prototype with a functional integration of formation and EOL-testing.

These methods enable the optimization regards time, quality and costs during the production.

Project Partner

The project FormEL is part of the competence cluster for battery cell production (ProZell) funded by the the Federal Ministry of Education and Research (BMBF). Project partners are the institute elenia of TU Braunschweig, the Institute PEM of RWTH Aachen, the University Bayreuth and the MEET of the University Münster.

Acknowledgement

This research project is funded by the Federal Ministry of Education and Research (BMBF), grant number 03XP0296D, and cared by Project Management Jülich.

The responsibility for the content of this publication lies with the author.

| Project members | ||||

|---|---|---|---|---|

| +49 (89) 289 - 26974 | thomas.roth(at)tum.de | Room: 1019 |

|

|