ProHybrid

Production technology for hybrid solid-state batteries with lithium metal anode – ProHybrid

The aim of the project „Production technology for hybrid solid-state batteries with lithium metal anode" (ProHybrid) is the production of solid-state batteries. In addition to that, scalable production processes are to be developed.

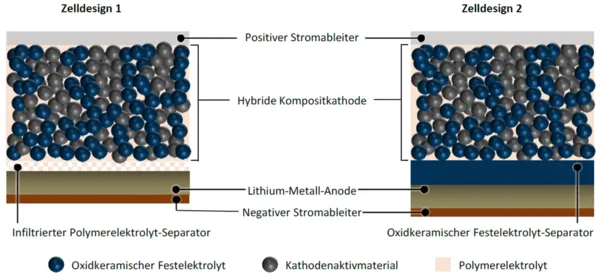

The unique feature of the ProHybrid project approach is the simultaneous use of two different solid electrolytes. An oxide ceramic solid electrolyte is to be used as the underlying support structure of a mixed cathode. A mixture of active material and a polymer electrolyte will then be introduced into this structure. This hybrid approach makes it possible to combine the good ionic conductivity and stability of the ceramic with the good contact surface of a polymer. For the separator, concepts made of ceramic or polymer electrolyte are to be tested. Metallic lithium is planned as the anode material.

The project partners involved in ProHybrid are:

- Omron Electronics GmbH (Project Coordinator)

- Technical University of Munich: iwb, EES

- Forschungszentrum Jülich GmbH: IEK-1, IEK-2, IEK-12/HI MS

- Brückner Maschinenbau GmbH & Co. KG

- J. Schmalz GmbH

- ZwickRoell GmbH & Co. KG

- VAF GmbH

The contribution of the Chair of Electrical Energy Storage (EES) to the ProHybrid project consists of the macroscopic modelling of the cell concepts. A modelling approach is to be developed and parameterised by tests on material and cell structures. The resulting models will then be used to accompany the further development of the cell designs.

Acknowledgement

This research project is funded by the Federal Ministry of Education and Research from the special fund "Climate and Transformation Fund" (grant number 03XP0580E).

The author is responsible for the content of this publication.

| Project members | ||||

|---|---|---|---|---|

| +49 (89) 289 - 26988 | marco.neudecker(at)tum.de | Room: 1021 |

|

|