Clean Fire

"Development of a biomass-gasifier and low-emission wood gas burner for heating and co-generation for low power ratings."

Reasons behind the research:

-

Particulate matter emissions

During conventional biomass combustion, particles between 0.01 and 10 µm are formed due to the alkalis in the fuel, which are then released into the environment with the rest of the emissions. These particles contribute to particulate matter pollution. A large part of the particles even have aerodynamic particle diameters between 0.05 and 1.0 µm. This is precisely the range of values that should be critically viewed by the people, as these particles can reach all the way into the pulmonary alveoli.

-

Power generation with smaller biomass combustion facilities

In the power range up to 100 kW, it has thus far been impossible to efficiently and successfully implement technologies for power generation from biomass. One cause of this is the deposits of dust and ash particles on the heat exchange surfaces. These deposits reduce the heat transfer and cause the heat exchangers to corrode. On the secondary side of the power generation, high temperatures are attainable in the operating medium, so that through the deposits, the electric efficiency is reduced significantly.

Goal of the project:

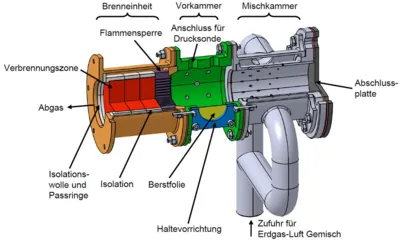

An autothermal countercurrent fixed-bed gasifier with a thermal capacity of 10 KW and an integrated burner head unit should be developed and optimized, to create the opportunity for continual and eco-friendly usage for the various areas of application, such as heating, power generation, and innovative condensation operation in the heat and power cogeneration operation. The gas produced should be combusted with a special burner located directly next to the gasifier (pore burner concept). The primary goal is an especially low CO and dust combustion of the gas and tar, so that the burner serves as a suitable heat source for the various heat exchangers.