Oxy-Coal Combustion

Through the ongoing reduction of the existing electrical capacity of nuclear power generators in Germany, which, despite considerable growth rates in the field, cannot be directly compensated by renewable energy sources, exists the demand for the development of the “classic” power plant park. Not just in Germany can the “Renaissance” of coal be observed.

Worldwide, coal power plant projects accompany the wish- stemming from the sense of ecological responsibility (greenhouse effect) and economical necessity (emission certificate prices)- to on the one hand reduce CO2 emissions, therefore raising efficiency, and, on the other, opening up possibilities for their storage. Technologies for the capture and storage of CO2 are recorded under the umbrella term Carbon Capture and Storage (CCS).

Oxyfuel, as one of these technologies, allows for the combustion of fossil fuel for power and heat generation, with an output of almost pure CO2 exhaust. The advantage of using this method as opposed to the conventional usage lies in the drastically reduced need for exhaust purification and separation. While the CO2 in the flue gas of the flow burning of coal still requires significant effort to be extracted, in oxyfuel power plants it is already in storable condition.

Goals

The research project “Oxycoal at the institute for energy systems”, sponsored by the Bavarian Research Foundation, aims to establish parameters for the controlled, staged oxyfuel- combustion of carbon dust. Cooperating partners in this project are the institute for combustion and power plant technology of the University of Stuttgart, as well as E.ON Energy AG, EnBW and Alstom Power Systems GMBH.

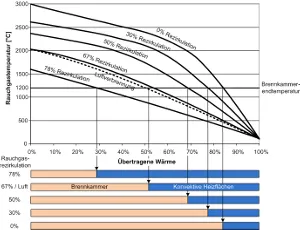

At the institute, a 210 kw combustion test facility with three vertically arranged burners is available for the project. These should be operated either over or sub stoichiometrically. The combination of both combustion methods provides for globally slightly over-stoichiometric conditions, combustion chamber outlet, and allows for the control of the flame temperatures.

With this configuration, these points, among others, should be investigated:

- Proof of the functional capacity of the innovative combustion concept

- Development of new carbon dust burners for non-stoichiometric use

- Investigation of the changed radiation pattern of oxy-coal-flames

- Investigation of the changed combustion behavior and pollutant formation in an oxygen-rich environment

- Creation of the database for the development of new steam generators for power plants on a commercial scale

For more information

Testing Facility: 210 KW combustion test facility.