OptiMaDyn

Optimisation of the Control Structures of Waste Incinerators through Dynamic Process Modelling and the Use of Innovative Monitoring Methods

Motivation

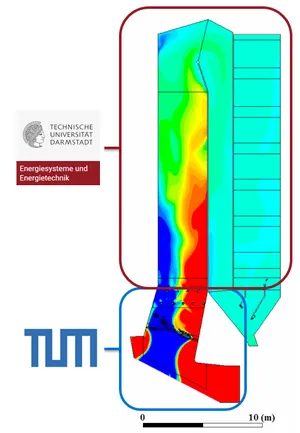

In a modern waste management system, besides recycling and composting, waste incineration also contributes to an efficient and environmentally friendly utilization of resources. A major challenge of waste incineration is the heterogeneous waste composition, as the fuel properties of this are hardly predictable. The energy released during incineration and the amount of steam generated in the waste incineration plant vary depending on the waste composition. This leads to suboptimal process control caused by uneven incineration. The resulting temperature fluctuations are partly responsible for an increased generation of pollutants and a fluctuation of the load stability in electricity as well as in heat generation. Innovative control methods promise a limitation of the thermal fluctuations through better process control and thus a more constant block power as well as a reduction in the generation of pollutants. In addition to a better control, the process behavior can be improved by early detection (monitoring) of disturbances and the dynamic behavior of the waste incineration plants can be understood by means of CFD simulations.

Project Goals

The aim of this project is to optimize the control of waste incineration plants by using dynamic process modeling in combination with an advanced monitoring system and detailed CFD- and DEM- simulations.

The optimized control is expected to lead to an increased load stability and flexibility while maintaining high reliability and low pollutant emissions. In addition, the detailed process and CFD modeling will contribute to a more fundamental understanding of the dynamic behavior of waste incineration plants. With the help of this, measures for increasing the efficiency in different operating modes will be found.

Funding

Federal Ministry for Economic Affairs and Climate Action

Project Partners

- Martin GmbH für Umwelt- und Energietechnik

- CMV-Systems GmbH & Co. KG

- Institut für Energiesysteme und Energietechnik der TU Darmstadt