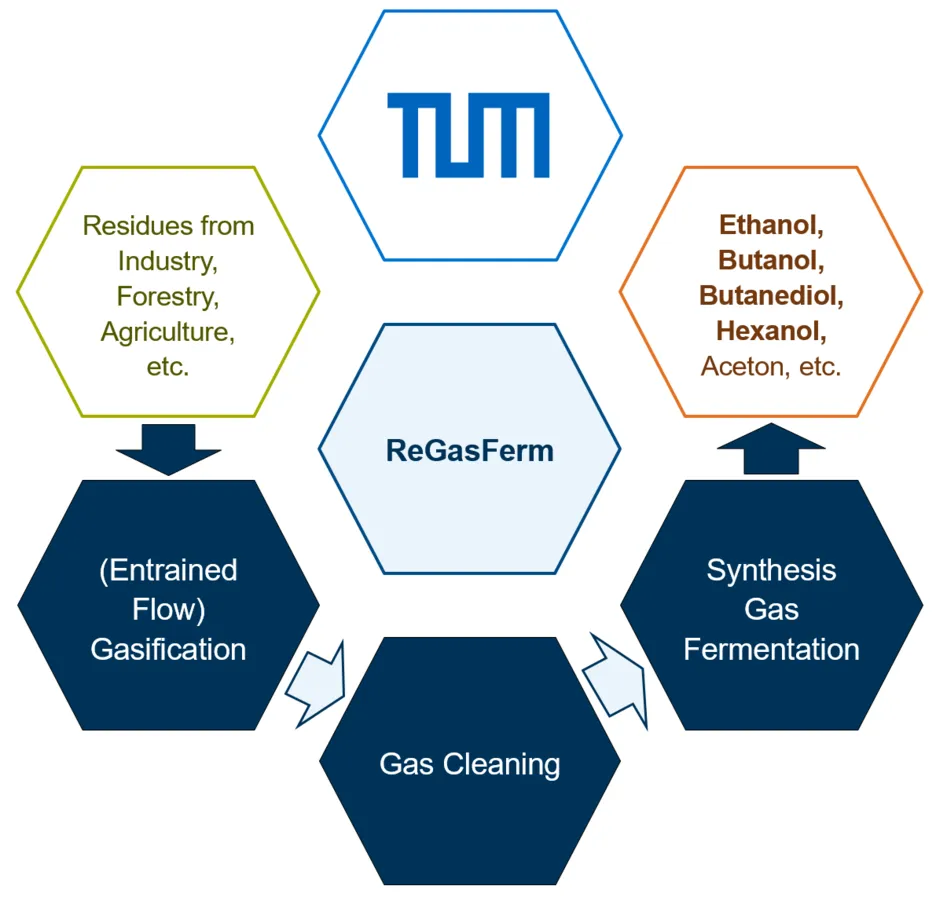

ReGasFerm

Utilization of biogenic residues in a biorefinery concept via entrained flow gasification with coupled gas fermentation for the production of basic chemicals

Synthesis gas from the gasification of biogenic residues can be used by acetogenic microorganisms as a carbon source for the production of C2-C6 compounds. However, the coupling of technologies within the framework of a synthesis gas biorefinery concept can only succeed if critical gas impurities are determined for the gas fermentation process and can be adapted and reduced immediately during gasification or in subsequent gas purification to such an extent that no negative influence on the biological conversion occurs. In the planned project "ReGasFerm", the technological combination of a biomass entrained flow gasification and a continuous biological conversion of the synthesis gas to alcohols (ethanol, butanol, 2,3-butanediol, hexanol) with an optimised gas purification is to be carried out. Gas composition and purity requirements of the synthesis gas for further use in gas fermentation will be defined for four selected bacterial strains, whereby the influence of individual impurities on kinetics and bacterial growth under different reaction conditions and process control will be determined. In addition, the understanding of the formation and degradation mechanisms of impurities during entrained flow gasification as well as the necessary gas analysis and measurement methodology will be further developed and expanded into the trace range. Methods for in-situ reduction of critical trace components (e.g. HCN) during the gasification process will be investigated. This will allow the development of a gas purification system that is coordinated for the coupling of entrained-flow gasification and gas fermentation and which, in the sense of a sustainable "zero waste" biorefinery, will be based in part on residual materials from the overall process. All in all, an integrative approach is to be pursued which highlights synergies between the technologies and project partners. The aim of the project is the continuous production of alcohol on a litre scale from the purified synthesis gases produced in the entrained-flow gasifier.

Project goals (LES):

- Characterisation of the gasification behaviour of the biogenic residues foliage and green waste in the entrained flow with oxygen

- Extension of the basic understanding of the formation and degradation mechanisms of trace substances relevant for gas fermentation during the entrained-flow gasification process

- Further development of the entrained-flow gasification process by primary reduction of trace components

- Successful trace analysis of synthesis gas impurities in purified synthesis gases

- Establishment of a gas purification system with residual materials arising in the process, which can meet the purity requirements for the synthesis gas for the fermentation process.

Project partners

Institute of Biochemical Engineering (visit homepage of Institute of Biochemical Engineering Link)

florafuel AG (visit homepage of florafuel AG Link)

Contact

Philipp Leuter