VERENA

Gasification processes with intern integration of excess electricity for flexible power generation and production of synthetic energy sources from residues

Motivation

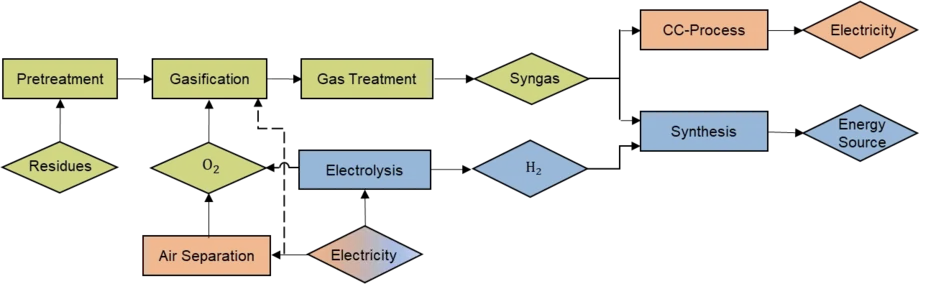

In polygeneration plants, electricity as well as synthetic energy sources, such as Fischer-Tropsch fuel, methane and methanol can be flexibly produced from a solid fuel. This is made possible by providing synthesis gas from the gasification of the fuel, which is either burned in a gas turbine or used for further synthesis. Thus, when electricity is required, it can be fed into the grid, while liquid or gaseous energy sources can be synthesized when there is a surplus of electricity. In addition, the integration of an electrolysis unit allows excess electricity to be incorporated by generating hydrogen to condition the synthesis gas and oxygen to gasify the fuel. This concept ensures a permanent operation of the gasifier, which makes the higher specific investment costs of a polygeneration plant easier to plan compared to conventional power plants, which in the future can only be used when electricity is needed (see figure).

Funding

Process chain of a polygeneration plant. Green: continuously in operation, red: electricity demand, blue: electricity surplus

Goals

The overall objective of the joint project is the development, testing and evaluation of technologies for the implementation of a polygeneration plant.

Due to its long experience, the Chair of Energy Systems at the TU München is working on the entrained flow gasification process. The main project goals of the LES can be summarized as follows:

- Experimental investigation of the gasification kinetics of biomass and residues under entrained flow conditions

- Experimental investigation of gas composition and gas treatment of the synthesis gas

- Modelling of entrained flow gasification of residues in CFD as well as design and optimization of a reactor on an industrial scale

- Modeling of different configurations of polygeneration plants in Aspen Plus

- Assessment of technical and economic feasibility

Funding

The project is funded by the German Federal Ministry of Economics and Energy (BMWi) under the grant number 03EE5044B.

Projekt partners

- TU Darmstadt

- TU Bergakademie Freiberg

- Forschungszentrum Jülich

- RWE Power AG

- Mitsubishi Hitachi Power Systems Europe GmbH

- Air Liquide Forschung und Entwicklung GmbH

- GTT Technologies

- Schmidtsche Schack/ARVOS GmbH

- GKN Sinter Metals Filters GmbH

- VER Verfahrensingenieure GmbH

- SUEZ Deutschland GmbH