The heat transfer to water at near-critical pressures conditions is important for conventional evaporators as well as for nuclear and solarthermal evaporator concepts. Due to the strong dependence of the fluid properties on the pressure, at supercritical pressures, the distinct heat transfer modes, normal, improved, and deteriorated, differ from those at subcritical pressures, resulting in unusual behavior of the heat transfer. In order to predict the occurrence of deteriorated heat transfer, various heat transfer models have been proposed over the last few decades. However, inconsistent results with respect to the heat transfer coefficient and onset of deteriorated heat transfer have been presented, owing to limited correlations or experimental data. Furthermore, all the models, which were developed for the heat transfer at near-critical pressure conditions, are based on steady-state experimental data. As a results, current models are limited in predicting the transient heat transfer during depresurization experiments from 250 to 180 bar: Unexpected high temperature peaks may occur. Accordingly, particularly with regard to accident conditions of supercritical nuclear reactor concepts, such as those occurring in a loss of coolant accident (LOCA), or the flexible operation of boilers, an accurate prediction of the transient heat transfer to water is desirable.

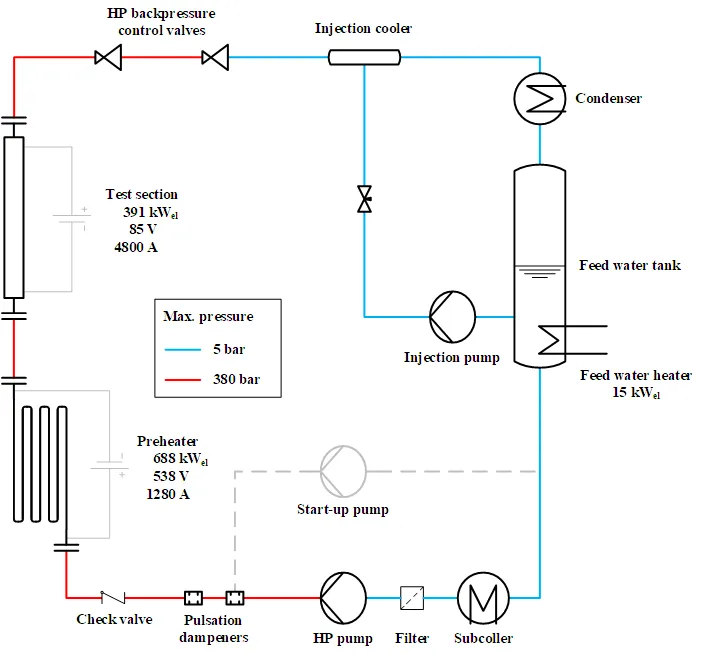

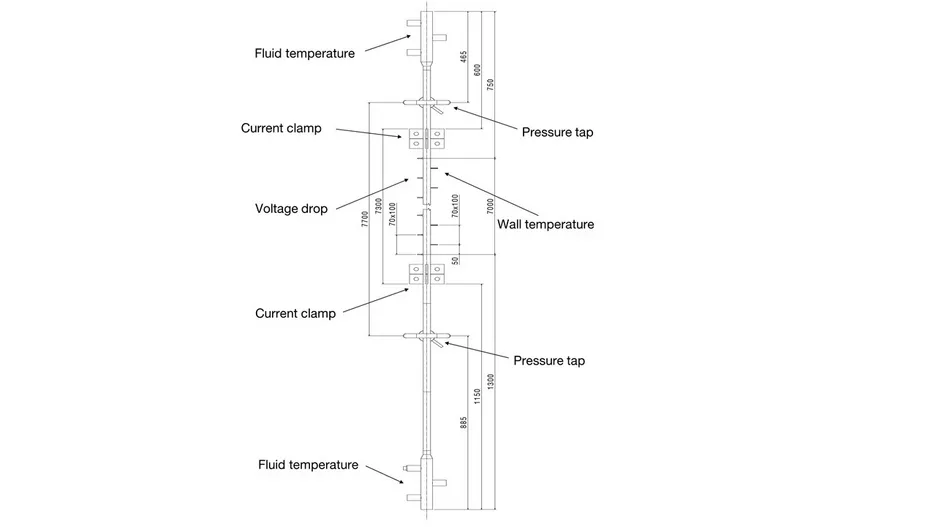

Therefore, the new high pressure evaporation test rig HIPER was designed and commissioned at the Institute for Energy Systems at the TU Munich. The high pressure evaporation test rig HIPER provides the opportunity to study the steady-state and transient heat transfer of evaporators at near-critical conditions for a wide range of parameters.