Wiring systems and power management

Challenge

The increasing electrification of components in future automobiles is creating a large and highly dynamic demand for power in the electrical wiring system. Electrified drives in hybrid and electric vehicles further reinforce this trend. Since the components of the vehicle electrical system cannot grow at the same rate for efficiency reasons, the large power fluctuations jeopardize the stability of the vehicle electrical system. Undervoltages can lead to functional restrictions or even the failure of control units.

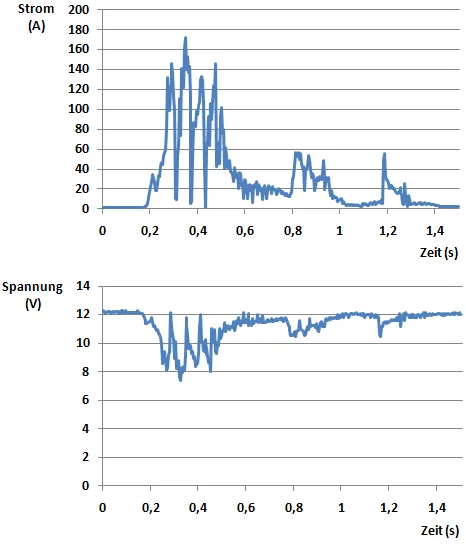

During an abrupt braking and evasive maneuver, for example, four chassis control systems alone produce current peaks of over 175 A in a few milliseconds, which in extreme cases cause voltage drops of up to 7.5 V (Fig. 1).

Goals

We are developing an intelligent and predictive power management system that makes it possible to coordinate power supply and demand and ensure the best possible fulfillment of all functions. In particular, existing power reserves are to be exploited and upcoming power peaks predicted, thus preparing the on-board network for them. In this way, onboard network stability is to be achieved in all situations.

Steps

Complexity management

In order to cope with the complexity of the numerous electrical components in the vehicle as well as the well over a hundred possible input variables of the prediction model, the entire system is based on the methods of cybernetics. These include, for example:

- Complexity reduction through data compression

- Separation of object and control levels

- Hierarchization and coupling of subnetworks

- Environmental coupling

- Soft modeling

Development of a prediction model

From the existing sensor and navigation data, we develop predictive driving situation and environment recognition. Mastering the complexity involved plays an important role, so that future information such as car-to-car or car-to-infrastructure information can be easily integrated through standardized sensor data fusion and information aggregation. Soft modeling with the theory of Linear Partial Information also enables statements to be made in the case of imprecise or incomplete information.

Development of a performance management system

We are developing a cybernetic power management system that records the current state as well as the current power reserve of the on-board network and compares it with the predicted requirements. If a gap is detected in the process, suitable countermeasure measures can be initiated preventively.

For example, if the environmental coupling system detects that the vehicle is traveling on a narrow mountain road in sub-zero temperatures, a rather sporty driver is at the wheel, and a tight curve is passed in two seconds, the risk of a power peak due to the activation of several driving safety systems such as ABS or DSC is very high. Without any noticeable loss of safety or comfort for the occupants, a power management system could, for example, briefly degrade the power of unimportant consumers in order to cushion the power peak and stabilize the vehicle electrical system voltage.

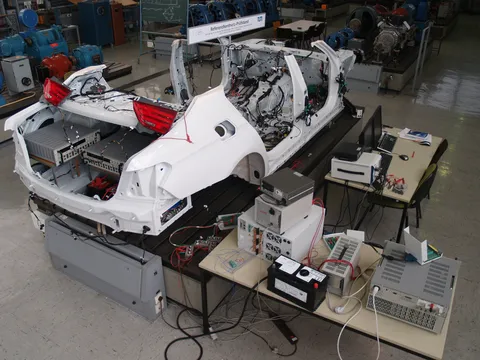

Verification on the test rig

In our vehicle electrical system test bench, we simulate a real vehicle electrical system in its environment (Fig. 2) so that all aspects of the wiring harness and the distributed power supply network are taken into account. Driving cycles or any driving situations recorded during test drives can be reproduced on the test bench. This allows management measures to be verified and optimized.

For more information on the structure of the test bench, please refer to Wiring System Test Bench.