Automated machine design

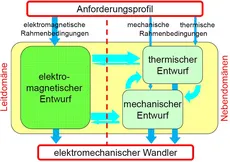

At the beginning of the new design of an electromechanical transducer, a variety of interactions between electromagnetic, thermal and mechanical conditions must be taken into account, which cannot be represented analytically. As a rule, the design process is therefore usually based on existing drive concepts, which are optimized for the respective application. Due to the lengthy optimization process, the consideration of an alternative approach for the solution of the drive system is no longer considered.

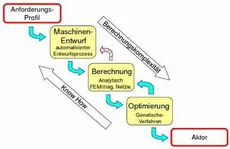

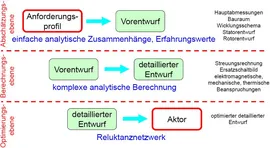

In order to allow the consideration of alternative concepts, a computer-aided machine design is necessary, which guides the developer through the entire design process without only redimensioning existing aggregates. In the context of this research project a development tool is created, which allows the developer to design an actuator in asynchronous or synchronous design in an extremely short time without neglecting the domains of mechanical or thermal design.

For automated further optimization of a design, a correspondingly detailed possibility of recalculation is required. The usual method with the help of the finite elements is not suitable because of the high necessary computation and/or time requirement. Alternatively, the recalculation is based on the theory of reluctance networks.