Inductive Charging – Wireless Power Transfer

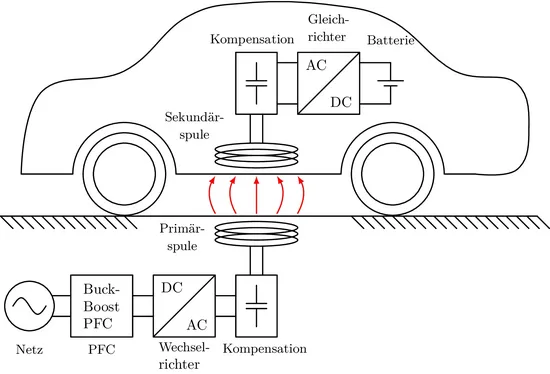

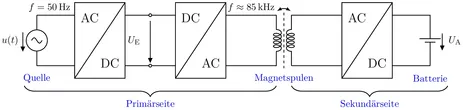

The electrification of the automobile requires not only a complete redesign of the vehicle but also a new (charging) infrastructure adapted to the changed requirements. Contactless, inductive charging systems (WPT - Wireless Power Transfer) are therefore another focus of our research.

Inductive charging systems offer numerous advantages, such as greater convenience, protection against vandalism and weather resistance. Furthermore, the easy handling offers the possibility to automate the charging process as well as to increase the range of electrically driven vehicles. Given standstill times of the vehicle during everyday use (inner-city parking lots, traffic lights, cab stands, etc.) can be used efficiently for battery charging without any special additional effort. It is also possible to implement a dynamic charging process during a journey by means of inductive energy transfer.

Challenges

The key challenges in contactless charging of an electric vehicle are overcoming the vehicle-related air gap and the parking-related position tolerance. The resulting low and position-dependent magnetic coupling requires power-electronic measures, e.g. in the form of capacitive power factor correction, so that the highest possible electrical efficiency can be achieved. In addition, the low coupling leads to high stray magnetic fluxes, which may pose a safety risk to persons in the vicinity of the charging station and may ignite surrounding objects (e.g. paper clip with paper, yogurt lid).

Goals

Depending on the requirements, two focal points can be identified in our research. On the one hand, we deal with physical circuit simulations for the analysis and design of resonant circuits. Here, for different requirements (power, coils, air gap, etc.), the appropriate circuit topology as well as the compensation network are to be defined and parameterized so that all operating requirements (current and voltage limits, efficiency) are met.

On the other hand, the improvement of the magnetic coupling or the coil systems is analyzed in simulations with the finite element method. Here, the focus is on the design of coil geometries that allow interoperable operation as well as certain tolerances in the arrangement of the coils to each other.