BioKond

BioKond - Biomass heating plants with highly efficient heat extraction through the innovative integration of an exhaust gas condensation heat pump

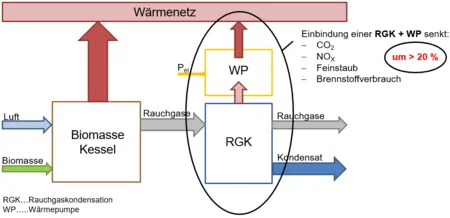

The current public debates on the topic of climate change and Fridays for Future clearly show that the use of new, innovative technologies is becoming increasingly relevant in order to sustainably reduce fuel requirements (e.g. wood) and emissions (e.g. CO2, dust, NOx). This also applies to the decentralized heat supply by means of biomass heating plants in Germany, Austria and Switzerland. The potential with over 1200 biomass-heating plants in the DACH region is enormous. Retrofitting many of these heating plants with heat pump technology and flue gas condensation can reduce particulate matter and CO2 emissions by over 20 %. For comparison, this corresponds to the value of the second agreement of the Kyoto Protocol for the reduction of greenhouse gases, to which the EU has also committed itself (20 % reduction of greenhouse gases compared to 1990). This clearly shows the relevance of the BioKond research project.

Targets for the more than 1200 biomass heating plants:

- Reduction of fuel demand and emissions by > 20 %.

- Introduction of condensing boiler technology in combination with heat pumps

- Integration of "power-to-heat" and "heat-to-power" concepts

- Development of a software package for planners "WDesign 2.0

Tools

- Software-supported dynamic energy system modeling (including WDesign, Aspen+)

- In situ data analysis of real plants ("real laboratories")

Detailed description of the project

As standard, biomass is burned in the boiler with the addition of air. The resulting heat is transferred to the local or district heating network by using heat exchangers. The idea now is to make the heat remaining in the flue gas usable by integration of flue gas condensation – also known as "condensing technology". With this, the flue gas is saturated and cooled to such an extent that it condenses out. The resulting low temperature latent heat is raised to a higher temperature level by a heat pump and fed back into the heating network.

The overall efficiency of a biomass heating plant can thus be increased by over 20 %. At constant heat demand, fuel consumption and thus CO2, NOx and dust emissions can be reduced by more than 20 %. In addition, the heat pump enables the biomass boiler to be switched off in inefficient summer operation, because the hot water supply can be realized entirely via the heat pump. In the further development of modern biomass systems, the integration of CHP plants as well as innovative power-to-heat and heat-to-power concepts for biomass heating plants will also be analyzed. The all-in-one software package "WDesign 2.0" for planners will summarize the developments and innovations of the project and conceptually round off the project together with a comprehensive report.

Funding:

We would like to express our sincere thanks for the support and funding of the project by the Agency of Renewable Resources and the Federal Ministry of Food and Agriculture.

Project duration: 01.10.2018 bis 30.09.2021

Funding reference: 22409517

Project supervisor: Yusheng Chen

Contakt: res-contact(at)tum.de